|  |

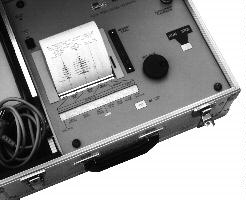

MD120 B WIRE ROPE DEFECTOGRAPH

The Instrument Set for Non-destructive Magnetic Testing of Wire Ropes

Since

1979, Meraster has supplied instruments to estimate the in-situ deterioration

of wire ropes around the world.

Since

1979, Meraster has supplied instruments to estimate the in-situ deterioration

of wire ropes around the world.

The operation of our NDT instruments is based on permanent magnet method, which was developed in Poland and is used throughout the world. Meraster's standard range of sensing measuring heads can be used for ropes ranging from 8 to 90 mm diameter. Custom designed heads are also available. For smaller ropes our MD-20 hand-held head-tester can be used.

Recently developed by Meraster, the MD120 recording system includes a specially designed portable chart recorder with additional data recording which can be transferred to a computer. This unique instrument has been designed as a helpful and comfortable tool, to meet the special needs of rope experts in industrial environments.

- Detecting the position of defects throughout the rope's entire length and depth

- Using mathematical integral method for easier readout of high density defects

- Zoom replay of recorded defects

- Diagram solid state memory

- Computer interface

- "Settings with rope code" memory

:

SPECIFICATIONS OF MD120 B DEFECTOGRAPH

AND ITS MEASURING HEADS

Rope size range

| GP series standard heads diameter | from 8 to 85 mm |

| heads GP-1 type | from 30 to 85 mm |

| heads GP-2 type | from 20 to 60 mm |

| heads GP-3 type | from 10 to 30 mm |

| head GP-4 | from 10 to 26 mm |

| head GP-5 | from 10 to 15 mm |

| heads GP-6 type | from 8 to 14 mm |

| Hand-held tester MD-20 as a head | from 8 to 22 mm |

| GM series light-weight heads | from 10 to 90 mm |

Rope types

wire ropes made of ferromagnetic steel, any form of construction

Detected rope defects

- defects characterised by stepwise changes in rope cross-section, i.e. broken wires, pitting corrosion, etc., are detected using inductive sensors in all heads

- larger losses in a rope's metallic cross-section, i.e. wear, corrosion in longer length etc. are detected using additional Hall-effect sensor in GP-1(h), GP-2(h),

- real distortion

GP-3(h) and GM series heads

all important defects to estimate rope deterioration; maximum sensitivity may be as high as 0.05% of nominal rope metallic cross-sectional area (but such defect readability depends on the rope's construction)

Defect positioning on rope length

with rope length converter RI, mounted in heads GP-1 type, GP-2 type,

GP-3 type, GM or separate for others

Defect positioning of depth inside rope

with heads equipped with double inductive sensors ("inner" and "outer"),

i.e. heads GP-1 type, GP-2 type, GM

Operating conditions

| Temperature | from -25° to + 40° C |

| for recording on paper | from 0° to + 40° C |

| Relative humidity | to 95% |

| for recording on paper | from 25 to 85% |

Dimensions and weight of measuring heads

See: "GP Measuring Heads", "GM

Measuring Heads", "MD-20 Wire Rope Tester"

- SIGNAL RECORDER.

Application range

This instrument is intended to record signals from magnetic sensing

heads for testing wire ropes. It may also be direct applied to recording

other electric signals within its sensitivity range 1mV/mm to 3.2 V/full

scale or it may be customised to record within another required range,

from 50 µV/mm.

Main modes

- chart feed at constant selectable speed

- chart feed synchronous to rope movement

- 4 measurement channels -

- 2 channels of inductive sensors (coils) signals,

- 1 channel of Hall-effect sensor signal,

- 1 channel of mathematical integration of the inductive signal,

- rope length printout in meters by 5 cm of chart,

- time marks every 1 second and 10 seconds

- printout of recorder settings, rope code settings, time and date

Example

Wire rope test chart

Recording method

Thermal array line printing head, printing on thermal paper on a roll

112 mm x 25m

- resolution 8 dots/mm

- channel format - overall width 103 mm

- Induction channels ± 18 mm each

- Hall channel ± 9 mm

- Integral channel 9 mm

- grid every 1mm and 10 mm in separate channels

0.05 to 10 m/s

Displayed rope speed range

0.05 to 9.99 m/s by 0.01m/s, over range indicated

Rope length display range 1 to 9999 m by 1 m reversible, up/down counting option, initial length setting capability

Length converter input

2 x 100 pulses/m (type RI)

Paper chart drive

1, 2, 5, 10 mm/m of rope or 1, 2, 5, 10 mm/second at synchro-feed rope

speed should be limited

| at 1 mm/m to 7.0m/s |

| at 2 mm/m to 7.0m/s |

| at 5 mm/m to 3.6m/s |

| at 10 mm/m to 1.8m/s |

"Zoom replay" memory capacity 18.75 m of rope or 18.75 seconds of recording

Acoustic signal of rope defect level

10, 20,....to 90% of full scale of the inner sensor channel (beeper

and also headphones)

"Settings & Rope Code" Memory

Capacity 100 items

Indicators

- liquid crystal display 2 x 40 characters

- RUN or STOP

- LED indicator POWER ON

- LED indicator PAPER OUT

- multicolour LED indicator of battery charging

| Type: | SRAM Memory Card |  |

| PCMCIA type I or II, | ||

| Capacity: | 512 kB to 4 MB, i.e. | |

| 300 to 2400 m of rope at synchro mode | ||

| or 300 to 2400 seconds (40 min) of recording | ||

| Recorded data: | 3 signal channels + integral channel | |

| at sampling rate 2.5 mm or ms | ||

| recorder settings, rope code, time, date | ||

| rope length counter | ||

| Data replaying: | • printing selected sectors with MD120 | |

| • with computer and software tools |

Required interface for data transfer from diagram memory to the computerPCMCIA port & professional, byte level software driver

Sensitivity range

Outer and inner coil channels

- sensitivity at constant chart feed in mm/s and at synchro mode (mm/m), for rope speed 1m/s: 1, 2, 5, 10, 20, 50, 100, 200 mV/mm , at input resistance 21.5 kohm

- actual sensitivity at synchro mode

- for rope speed 0.05 to 10m/s depends on: "nominal sensitivity" x "value of rope speed in m/s"

- at speed less than 0.05 m/s: as for 0.05 m/s (max. sensitivity 1 mV/mm x 0.05 = 0.05 mV/mm)

- 0.1, 0.2, 0.5, 1, 2, 5, 10, 20 mV/mm

- differential input voltage

with DC component cutting, 0-400 mV

- 4 sensitivity levels

- running integral range 0.1 to 9.99 m or s

- AC Mains 220 V, 80 VA; other AC Mains voltages on request

- DC 12 V, 50 W

- Internal rechargeable battery for 4-6 hours of operation without external power

- deep discharge protection

- recharging while external power is connected

47.5 x 37 x 17.5 cm

Weight

with standard accessories 13 kg

Zawada

NDT

![]()

Language

versions

English Main

Page

MD120 Wire Rope Defectograph:

PC Card,

Optional Hardware and Software for PC

E-mail:

zawada@z-ndt.com

Fax:

++48 32 376 7900

Phone:

++48 32 271 6231

Mail:

Zawada NDT

ul. Tatarkiewicza 8

PL- 41-819 Zabrze

POLAND

Office/Visit:

ul. Roosevelta 120 B-5

(GPS: Roosevelta 118)

41-800 Zabrze