WIRE ROPE INSPECTION |

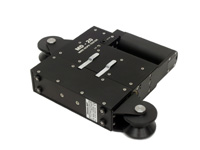

MD-20 WIRE ROPE TESTER

MD-25 WIRE ROPE TESTER

An Instrument to Detect Damage in Wire Ropes

The

MD 20 / MD 25 Wire Rope Tester is a simple to use instrument to test the condition

of small diameter ropes. It indicates the occurrence of rope defects that

exceed the set level of detectability.

The

MD 20 / MD 25 Wire Rope Tester is a simple to use instrument to test the condition

of small diameter ropes. It indicates the occurrence of rope defects that

exceed the set level of detectability.

It can also be used as a sensor head connected to the more advanced MD120 or MD121 Defectograph, which determines defects more accurately, or can be connected to computer with MDNV USB Data Logger or to a general purpose recorder. H-versions, i. e. MD-20H and MD-25H versions are intended for tester application as a test head, where additional LMA channel output is provided for recording.

Applications

The instrument is designed to detect stepwise defects such as wire

breaks and localised corrosion.

It is intended for quick tests and can be used even by non-skilled personnel. Provided with a handle and light in weight, it can be used as a hand-held instrument during visual inspection to ensure that no important defect is missed and that any damage inside a rope is detected. The instrument can also be fixed in position (i.e. not hand held). Any signaling of serious defects identified by the tester means that the rope's condition should be checked by an expert.

Operation

Operation

The instrument's operation is based on the permanent magnet magnetic,

a world renowned method developed by the Academy of Mining and Metalurgy

in Cracow. During the rope's passage through the tester defects are signalled

by a beep sound, a yellow light-emitting diode flashing and a red LED operates,

remaining on until the instrument is switched off, using the on-off switch.

If there are no defects in rope that exceed the detection value set, then

the green LED is illuminated

Technical Data

- Range of rope sizes

- Sensitivity:

- Speed of checked rope:

- Indicators:

- LB (red) - low battery/charging

- OK (green) - lack of rope defects

- D (yellow) - defect (flashing at defect location)

- DM (red) - faulty rope (continuous light)

- Sound beeper

- Supply:

- Operating temperature:

-

Output socket:

stereo jack coupling - Damage detection signal in basic versions or LMA signal in H versions

- LD (LF) inductive transducer signal

- Length: 205 mm

- Width: 46 mm

- Height with rollers (hand operated, full diameter range): 280 mm

- Height with sliding guides for up to 18 mm diameter (mounted tester): 243 mm

- Height without rollers and sliding guides (frictionless rope passage through the mounted tester): 163 mm

- Weight: MD-20 4,5 kg / MD-25 4,9 kg

MD-20 and MD-20H: 8 to 22 mm diameter

MD-25 and MD-25H: 10 to 25 mm diameter

suitable for detecting any typically broken wire

Detection level, adjustable by ten-turn potentiometer

Recommended 0.1 to 2.5 m/s (6 to 150 m/min); results are independent of rope speed

4 light-emitting diodes

Ni-Cd or NiMH 8.4-9V/100-160 mAh rechargeable battery (included)

or 9V type 6F22 primary battery

Rechargeable battery can be charged inside the instrument by internal circuits and external power supply

(100-240 V a.c. to 12 V d.c. version included)

standard MD-20/25/20H/25H: -10 to +40°C

MD 20L: –25 to +40°C

zawada@z-ndt.com Fax: +48 32 376 7900 Phone: +48 32 271 6231 www.z-ndt.com

Mail: Zawada NDT, ul. Tatarkiewicza 8, PL- 41-819 Zabrze, POLAND

Office/Visit: Zawada NDT, ul. Roosevelta 120 bud. B-5 (GPS: Roosevelta 118), 41-800 Zabrze, Poland